What is Anerobic Digestion?

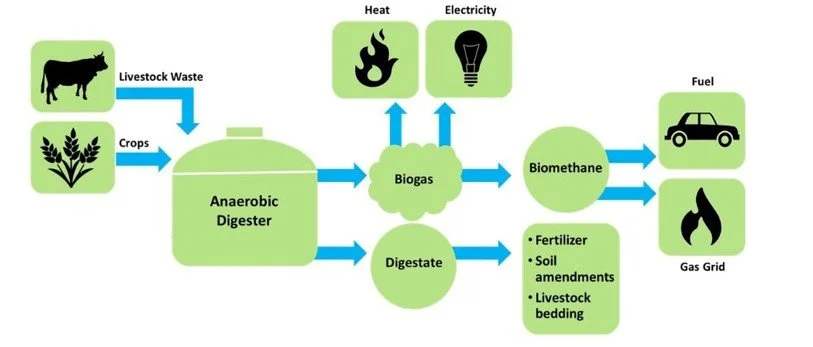

Anaerobic digestion is a natural biological process where micro-organisms (bugs) break down organic material in the absence of oxygen.

This happens in a sealed tank known as an anaerobic digester.

1. What Feedstocks Are Used?

Agricultural AD plants typically process materials such as:

• Livestock Slurry and manure from cattle, pigs, and poultry

• Energy crops and residues like Grass/Sorghum/Maize Silage and Energy Beet

• Food processing by-products from dairies, breweries, or grain processing

• Agricultural organic waste streams such as sugarcane bagasse, straw, and distillery grains

These materials are rich in carbon, fiber, and nutrients, making them ideal for biogas production.

2. How the Process Works on a Farm

Feedstock collection

Crop based materials are harvested and ensiled the same way you would for livestock feed i.e Silage harvesting. Manures are delivered to the site fresh daily from local farms using tankers or trailers.

Feeding

The crop-based materials are fed into a stationary feeder wagon where they are added to the primary tank over the course of a day. The liquid manures are delivered to a pre-pit tank where they are stored and pumped into the primary digester over the course of a day also.Digestion

The mixture enters a sealed digester, where it is mixed and kept warm (usually 45–50°C) which creates the perfect environment for anaerobic digestion.

Microbial breakdown

Microbes break down the material in four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis until it creates a renewable gas known as biogas.Biogas production

The biogas which contains 55% Methane (CH₄) and 45% carbon dioxide (CO₂) rises to the top of the tank and is captured in the dome roof.Upgrading

The biogas is sent to a purification system which separates the CH₄ and CO₂ in the biogas to produce biomethane (Renewable natural gas) and Biogenic CO₂.

Whats left?

What remains is a nutrient-rich fertiliser known as digestate. This is a high quality organic fertiliser rich in organic matter and available nutrients which can be applied back onto the land to grow more sustainable crops.

3. What can biogas be used for?

Biogas can be:

Used as fuel in a Combined Heat and Power unit (CHP) to produce heat and electricity

Used in a gas boiler to create heat

Biomethane can be:

Injected into the natural gas grid as a direct replacement for natural gas

Used in industry to create steam or process heat

Compressed for use as a transport fuel in trucks, tractors etc.

Used in a boiler on farm to create heat for drying grain, hay, or dairy processing

Each providing new income streams and energy independence for farms in regional areas

Biogenic CO2 can be used in:

The carbonation of soft drinks, sparkling water and beer (makes bubbles in beer)

Meat packaging to preserve the product

The manufacture of dry ice

Greenhouses to boost plant growth

Welding and cutting gases

Fire extinguishers

Createing E-fuels

Long term geological CO2 storage to reduce GHG emissions

A lot of valuable products from something you see on every farm!

4. The Role of Digestate in Farming

Digestate is a high-quality, stable fertiliser with improved nitrogen availability compared to raw manure. It:

• Reduces the need for chemical fertilisers

• Improves soil structure

• Releases nutrients more predictably

• Has lower odour and pathogen levels than untreated slurry

Digestate can be separated into:

• Liquid fraction – High in available Nitrogen and ideal for precision low emission spreading

• Solid fraction – High in Phosphorus and Potassium as well as organic matter. Used as a soil conditioner or green bedding material.

5. Why Agriculture Benefits Strongly from AD

• Cuts down on-farm emissions methane from manure is captured, not released. Odor from applying manure is reduced and pathogen risks eliminated.

• Improves nutrient management digestate boosts soil organic carbon and microbial activity, improving water infiltration and retention which is increasingly important in Australian low-OM soils and drought stricken regions

• Creates new revenue Manures, residues and forage crops increase in value, allowing farmers to make additional income from energy production and carbon credits

• Supports energy resilience from during increasingly volatile energy markets

• Makes farms more circular and self-sufficient Digestate can replace large volumes of synthetic NPK fertilisers while the biogas can be used to displace diesel fuel in tractors etc.

6. Why AI Matters in Agricultural AD

Farm-based feedstocks are highly variable, especially grass, silage, and manure. Our rhobots.ai integration system helps by:

• Predicting biogas yields from mixed feedstocks

• Optimising the digester’s biological conditions

• Reducing downtime and instability

• Maximising methane output

• Improving nutrient recovery and digestate quality

It transforms AD from a manually tuned system into a smart, self-adjusting energy and nutrient engine.

The technology has already demonstrated exceptional results in live industrial environments. In a recent deployment at Carbon AMS in Ireland, the Rhobot.ai Siemens Edge solution delivered:

39 percent reduction in parasitic load

2.5 percent increase in gas output

Highlighting its potential to drive significant operational and sustainability gains across energy and manufacturing industries.